Telemecanique XCKP2149G11 | Limit switch, Limit switches XC Standard, XCKP, plastic roller lever Ø 50 var.length, 1NC+1 NO, snap, Pg11

EGP3,060EGP5,773 (-47%)

Telemecanique XCKP2149G11 | Limit switch, Limit switches XC Standard, XCKP, plastic roller lever Ø 50 var.length, 1NC+1 NO, snap, Pg11

Telemecanique XCKP2149G11 | Limit switch, Limit switches XC Standard, XCKP, plastic roller lever Ø 50 var.length, 1NC+1 NO, snap, Pg11

Telemecanique XCKP2149G11: Comprehensive Overview

Introduction

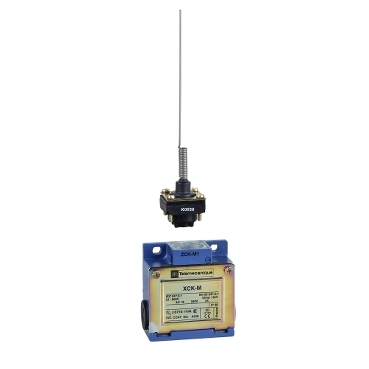

The Telemecanique XCKP2149G11 is a highly durable and versatile limit switch, designed for demanding industrial applications. As a part of Schneider Electric’s Telemecanique sensor range, it ensures precision, reliability, and operational safety in various automated systems. Limit switches like the XCKP2149G11 play a vital role in controlling machinery movements by detecting end-of-travel positions or ensuring equipment stops when required. This guide covers the key features, benefits, and applications of the XCKP2149G11.

About Telemecanique (Schneider Electric)

Telemecanique, under the umbrella of Schneider Electric, is renowned for its high-quality sensors and automation solutions. For decades, it has been at the forefront of innovation in industrial automation, offering reliable products that enhance safety, productivity, and efficiency across multiple sectors. The XCKP2149G11 continues the legacy by providing advanced control solutions in a variety of industrial settings.

Technical Specifications of XCKP2149G11

The XCKP2149G11 offers a range of advanced specifications that make it suitable for industrial applications:

- Type: Limit switch with a roller lever actuator

- Contacts: 1 normally open (NO) and 1 normally closed (NC) contact

- Rated Operational Current: 6 A at 240 V AC

- Housing Material: Durable thermoplastic casing

- Protection Rating: IP66 (dustproof and protected against powerful water jets)

- Operating Temperature: -25°C to +70°C

- Actuator Type: Rotary head with a fixed, stainless-steel roller lever

The switch is known for its precise operation and rugged build, making it suitable for harsh environments.

Applications of XCKP2149G11

The XCKP2149G11 is used in a variety of industrial applications, including:

- Material Handling Equipment: Detects the position of conveyor belts and ensures safe operation.

- Packaging Machines: Helps in automating the start and stop of processes when materials reach defined positions.

- Automated Production Lines: Provides end-of-travel detection, protecting machinery from overrun or misalignment.

- Cranes and Hoists: Prevents overtravel and ensures safety in material lifting operations.

The switch is ideal for environments that demand high levels of reliability and precision.

Features of the XCKP2149G11

- Robust and Compact Design: The XCKP2149G11 is built to withstand challenging industrial conditions, thanks to its rugged thermoplastic housing and IP66 protection rating.

- High Precision and Repeatability: The rotary head with a roller lever actuator ensures accurate, repeatable performance, essential for tasks requiring precise end-of-travel detection.

- Environmental Protection: Its IP66 rating makes it resistant to dust and water, ideal for harsh environments like factories, warehouses, and outdoor installations.

Installation and Setup

Setting up the XCKP2149G11 is straightforward:

- Mounting: Secure the switch on the machinery, ensuring the roller lever actuator aligns with the moving part it will monitor.

- Wiring: Connect the switch to the control system using its screw clamp terminals. Ensure proper wiring of the NO and NC contacts based on system requirements.

- Testing: After installation, test the switch to ensure it correctly activates or deactivates machinery as the roller lever is triggered.

Safety Standards and Certifications

The XCKP2149G11 complies with the following safety standards:

- IEC 60947-5-1: Standards for control circuit devices.

- ISO 14119: Safety standards for interlocking devices.

- EN/IEC 60204-1: Safety of machinery and electrical equipment.

These certifications ensure that the XCKP2149G11 meets global safety requirements, making it an essential part of any safety-critical industrial system.

Maintenance and Longevity

To maintain the XCKP2149G11’s performance over time:

- Regular Inspection: Check for wear and tear, especially on the roller lever actuator.

- Cleaning: Keep the switch free from dust and debris to maintain optimal functionality.

- Calibration: Periodically verify that the switch activates at the correct position and that the NO and NC contacts are functioning properly.

Reviews

There are no reviews yet.