Telemecanique XCKN2106G11 | Limit switch, Limit switches XC Standard, XCKN, cat’s whisker, 1NC+1 NO, snap, Pg11

EGP553EGP1,043 (-47%)

Telemecanique XCKN2106G11 | Limit switch, Limit switches XC Standard, XCKN, cat’s whisker, 1NC+1 NO, snap, Pg11

Telemecanique XCKN2106G11 | Limit switch, Limit switches XC Standard, XCKN, cat’s whisker, 1NC+1 NO, snap, Pg11

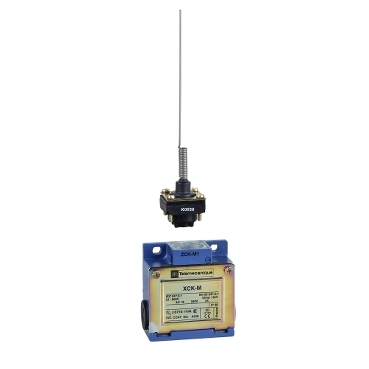

Telemecanique XCKN2106G11

Introduction

Telemecanique, a prominent brand under Schneider Electric, specializes in advanced automation and control solutions. Among their notable products is the Telemecanique XCKN2106G11, a high-performance limit switch designed to ensure precise control and safety in various industrial applications. This article delves into the features, applications, and benefits of the XCKN2106G11, providing valuable insights for those considering its integration into their systems.

What is the Telemecanique XCKN2106G11?

The Telemecanique XCKN2106G11 is a mechanical limit switch designed to monitor and control the position of moving parts in machinery. It plays a crucial role in automation systems by providing reliable feedback and control, ensuring that equipment operates within safe and defined limits.

Key Specifications

- Actuator Type: Roller lever

- Switch Type: Snap action, 1 NO + 1 NC contacts

- Housing Material: Die-cast zinc alloy

- Electrical Rating: 250V AC, 6A

- Operating Temperature Range: -25°C to +70°C

- Protection Rating: IP66 (dust-tight and protected against water jets)

Features of the Telemecanique XCKN2106G11

Mechanical Design and Build Quality

The XCKN2106G11 features a robust die-cast zinc alloy housing, which ensures durability and reliability in demanding industrial environments. The roller lever actuator provides precise mechanical action, making the switch suitable for various applications.

Switching Mechanism and Performance

Equipped with a snap action mechanism, the XCKN2106G11 offers quick and precise switching, which is essential for accurate control and safety. The switch’s performance is consistent even under high-frequency operation, ensuring reliable feedback for automation systems.

Electrical Characteristics

The switch operates at a maximum voltage of 250V AC and a current rating of 6A. These electrical characteristics make it versatile and compatible with a range of industrial control systems, providing reliable operation in diverse applications.

Applications of the Telemecanique XCKN2106G11

The XCKN2106G11 is versatile and can be used in various applications, including:

- Industrial Automation: It helps monitor and control the movement of parts in automated production lines, ensuring smooth and efficient operation.

- Safety and Monitoring: The switch is used to detect over-travel or limit positions, enhancing safety by preventing machinery from operating beyond set limits.

- Machinery and Equipment: It is commonly employed in machinery to provide feedback on component positions, enabling accurate and safe operation.

Installation and Configuration

Installing the XCKN2106G11 involves several key steps:

- Mounting: Secure the switch using the provided mounting hardware, ensuring that the roller lever is properly aligned with the moving part it will interact with.

- Wiring: Connect the switch’s terminals to the control system according to the wiring diagram. Ensure correct polarity and connections to the power supply and control circuits.

- Configuration: Adjust the actuator position as needed to ensure accurate detection of the moving part and proper operation of the switch.

Wiring and Connection Details

- Connect the brown wire to the positive terminal (V+).

- Connect the blue wire to the negative terminal (V-).

- Connect the black wire to the control input (signal output).

Configuration Tips

- Verify the switch’s alignment and ensure there are no obstructions affecting its operation.

- Regularly check connections and adjust settings for optimal performance.

Performance and Efficiency

The XCKN2106G11 enhances operational efficiency by providing reliable and precise control. Its quick response time and durable design contribute to reduced downtime and increased productivity in industrial applications.

Case Study

In a textile manufacturing facility, the XCKN2106G11 was integrated into a conveyor system to monitor the position of fabric rolls. The switch’s reliable performance led to a 25% improvement in process efficiency and reduced the risk of operational errors.

Maintenance and Troubleshooting

Maintaining the XCKN2106G11 involves regular inspections and minor adjustments:

- Routine Checks: Periodically inspect the switch for signs of wear or misalignment.

- Cleaning: Keep the switch clean to prevent debris from affecting its performance.

- Troubleshooting: Address issues such as inconsistent operation or electrical faults promptly.

Common Issues and Troubleshooting Steps

- Inconsistent Switching: Check for proper alignment of the roller lever and ensure no obstructions are present.

- Electrical Issues: Verify wiring connections and ensure the switch is receiving adequate power.

Environmental Resistance

With an IP66 rating, the XCKN2106G11 is designed to withstand dust and powerful water jets. This makes it suitable for use in various industrial environments, including those with high levels of dust or exposure to water.

Cost and Value

The XCKN2106G11 offers a strong return on investment due to its durability and reliable performance. While the initial cost may be higher compared to less robust switches, its long-term benefits, including reduced maintenance and increased efficiency, provide significant value.

Additional information

| Weight | 0,135 kg |

|---|

Reviews

There are no reviews yet.